Earn Money Form Affilate Program , Earn Money Form You Home , Earn Money Form Sport , Earn Money Form Your Parent , Earn Money Form Your Pay Out Ean Money Online , Earn Money Form Sale Product Earn Money Trip , Earn Money Form Adsense Google ,and then get money

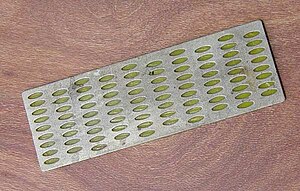

The above is the twice weekly payment I received from SponsoredReviews .com. So far, I can count myself lucky with SponsoredReviews .com because I have a constant supplies of assignments to review.

Why I get assignments from SponsoredReviews ?

1) I have many blogs in different categories;

2) SponsoredReviews advertisers are usually concentrated on travel, women, parenting and food industries and these are very huge industries, in case you do not know.

3) I am one dead persistent, pesky blogger who never give up. I login twice a day, bid and counter-bid;

4) I am immune to rejections and I got many blogs to try my luck;

5) My blogs template are decently presentable (ok, very impressive actually) and attractive to advertisers;

6) My blogs’ topics are mostly niche and I write very well;

7) I am one lucky blogger;

What I like about SponsoredReviews ;

1) The ability to check out advertisers before I offer to write for them and set my own price;

2) The thrills of telling advertisers who want to pay me USD5 (and I only get USD3.25) for 300 words on a PR4/10 to go fly kite; (ok, not really but I do get to decline and it is empowering)

3) The quality of their advertisers; (well so far, so good, no sleazy sites)

4) The ease of moving around their dashboard;

5) No frustrations of fighting with other people to grab an opp aka no stress;

6) Payout is good as I usually get between USD15 to USD50 per assignment; (my lowest price on my blogspot blog is USD20)

But I wish SponsoredReviews will give me some referral. This is a good way to create publicity and also draw more advertisers to them.

Tip for the day : AVOID doing SEO companies reviews if you are at their mercy with bans and benches। You know what I mean? These are the most pain-in-the-ars* advertisers because they think they are kings and will be very critical of our reviews. Sometimes I feel like telling them, “Hey, take this five bucks and the door is over there.”